Steel structure bulk grain warehouse

Release time:

2022-06-15

Project Description of Steel Structure Grain Bulk Warehouse

We developedSteel structure grain bulk warehouseThe characteristics of short construction period, good heat preservation effect, excellent waterproof performance, leading grain storage quantity and significant cost advantage have been fully recognized and promoted by the majority of users.

Directory

(I) Overview

(II) steel structure body

(III) wall pressure system

(IV) gable column compression system

(V) grain gate system

(VI) roof and wall insulation system

(VII) wall and roof waterproofing system

(VIII) hemming system

(IX) grain surface air feeding system

(X) ground system

(XI) Some engineering cases

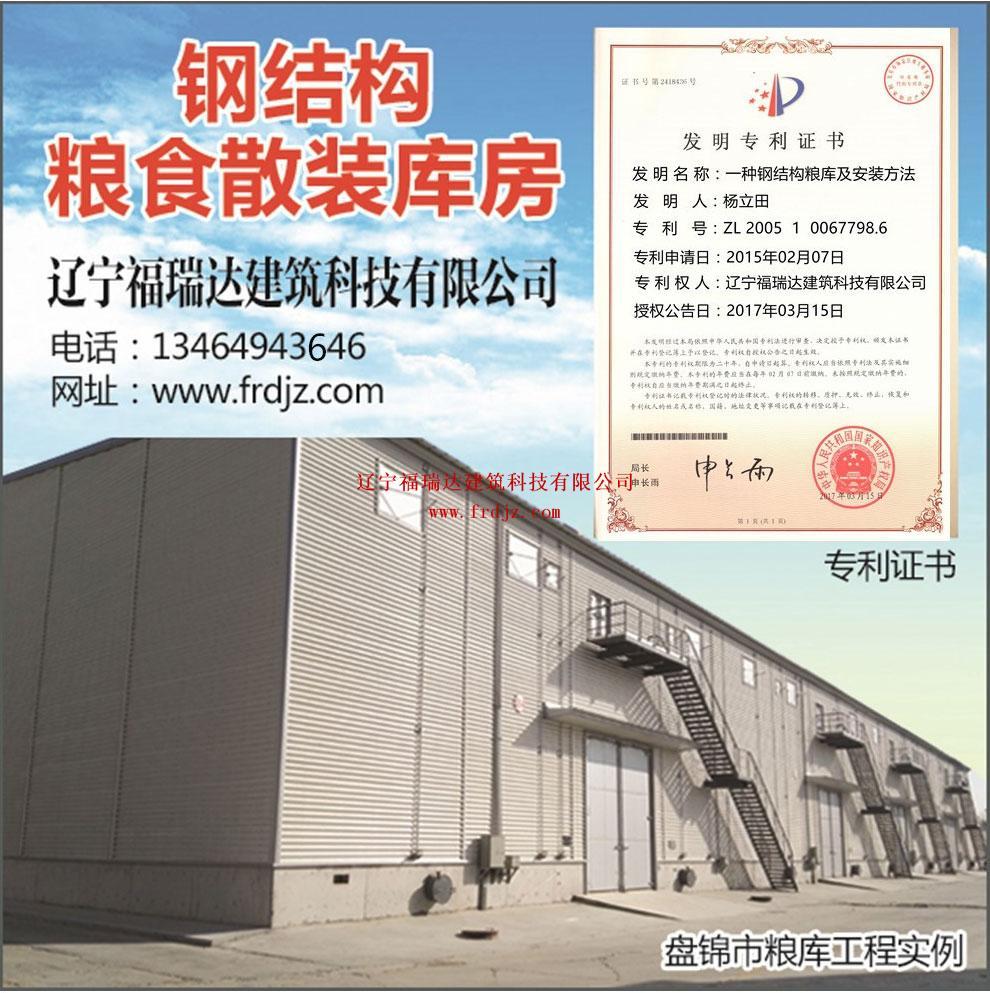

(XII) Patent Certificate

(I) Overview

Liaoning FuRuida Construction Technology Co., Ltd. launched a patent technology property rights of grain bulk grain depot and reinforced concrete warehouse or simple canopy has very important advantages compared:

1Construction period: Taking the corn warehouse with a construction area of 12000 square meters and 50000 tons of grain storage as the standard, the traditional bulk grain warehouse used to use reinforced concrete frame structure, and the construction period was 4 months. After completion, natural ventilation was required to ensure the drying of the wall, and it took 3-6 months. The construction period of our steel structure bulk grain storage technology is only 2 months, and it can be used immediately after completion.

2Thermal insulation: The traditional bulk grain depot is made of reinforced concrete and masonry, so it has strong thermal conductivity, and the thermal conductivity is generally 0.39-0.42W/mk. The technical insulation of our steel structure bulk grain depot adopts inner and outer double-layer heat-resistant glass wool and static air layer physical insulation (thermos tank principle), and the thermal conductivity can reach 0.005-0.3W/mk.

32. Waterproof performance: The roof of the traditional bulk grain depot adopts the traditional coiled material for waterproofing, and the wall adopts the waterproof coating for waterproofing. However, these traditional waterproofing measures all have the phenomenon of internal water vapor seepage after the aging of the waterproofing material, and the grain is often lost due to floods. Our steel structure bulk grain depot technology uses color steel plate with 360-degree glued lock and double lock sealing method to make the roof, which has very good waterproof property, and the roof can move with thermal expansion and contraction, which can reach 100 leakage prevention compared with the traditional bulk grain depot roof and similar grain depot roof. The wall is also the application of color steel plate, and the use of a unique node waterproof measures, there is no water infiltration and other phenomena, to prevent the loss of food due to flooding.

4In terms of grain reserves: The traditional bulk grain depot has a grain surface elevation of 6 meters and low reserves. Our steel structure bulk grain storage technology grain loading height can reach 7 meters and above, and compared with similar grain storage, grain direct contact with the wall, greatly increasing the storage capacity of grain, effective use of land resources and reduce the cost of storage.

5In terms of construction costAccording to the standard of corn warehouse with a construction area of 12000 square meters and 50000 tons of grain, the cost per square meter of traditional bulk grain depot is about 1300 yuan. Our steel structure bulk grain depot technology costs only about 900 yuan per square meter. Taking the rice warehouse with a construction area of 3800 square meters and 16000 tons of grain as the standard, the cost of the traditional bulk grain depot is about 3000 yuan per square meter; the cost of our steel structure bulk grain depot technology is only about 1500 yuan per square meter.

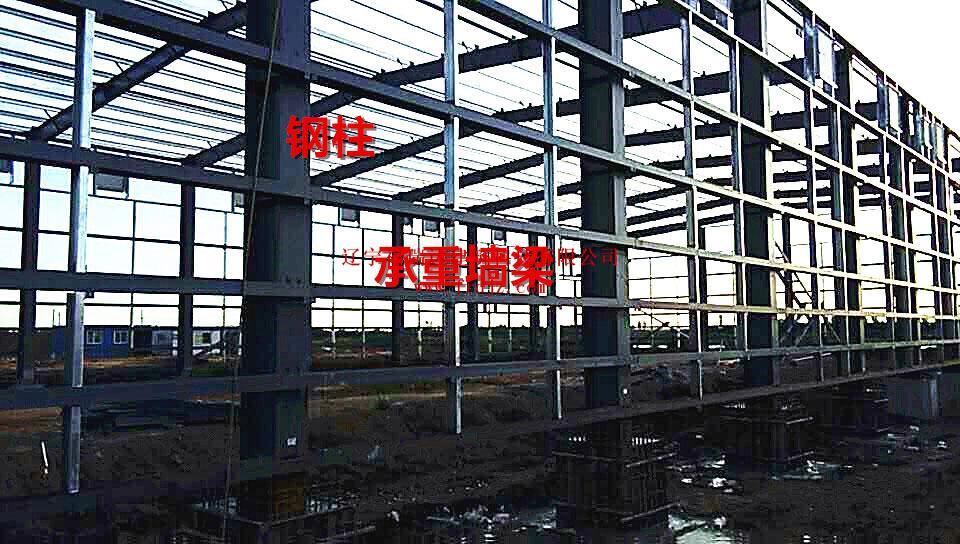

(II) steel structure body

1. Main structure

Portal steel frame structure is adopted, with an average span of 20-80 meters and unlimited length. The specific size shall be subject to Party A's site. According to fire prevention requirements, the single area shall not exceed 12000 square meters, the bay shall be 6 meters, the roof structure with double slopes and unorganized natural drainage. Steel columns and steel beams are made of high-strength steel plates produced by Angang or Benxigang, processed into welded H-beams. Anshan, Tianjin large-scale enterprise national standard steel. The surface of the component shall be derusted by mechanical shot blasting, and the derusting level shall reach Sa2.0 or Sa2.5. Two coats of 30 um alkyd antirust primer and two coats of 30 um alkyd topcoat shall be sprayed for indoor anti-corrosion. The total thickness of the paint film is 120 um for indoor anti-corrosion. Two coats of 30 um epoxy anti-rust primer and two coats of 30 um epoxy finish are used for outdoor anti-corrosion. The total thickness of the paint film is 120 um indoors. The column-column connection and the column-beam connection are all connected by 10.9-grade high-strength bolts, and the other connections are connected by 4.8-grade galvanized bolts. The elevation of the eaves head is 2.5 meters higher than the grain bearing surface, and the roof slope is 5%-10%. All steel components are manufactured in the factory, and the quality assurance conforms to the national standard "Steel Structure Manufacturing and Construction Specification 50205" and "Grain Bungalow Warehouse Design Specification GB50320. The foundation adopts independent cup-mouth foundation.

2. Performance index (taking Anshan area as an example)

Snow load 0.55KN/m2

Wind load 0.55KN/m2

Dead load 0.3KN/m2

Physical parameters for design of main grain

| Category | Mass density (kg/m3) |

Gravity density (kn/m3) |

Standard value of load surface weight of single-layer stack (kg/m2) |

| Rice |

550 |

6.0 |

1.40 |

| Rice |

790 |

8.5 |

1.90 |

| Corn |

730 |

7.8 |

1.80 |

| Wheat |

750 |

8.0 |

1.80 |

| Soybean |

710 |

7.5 |

1.60 |

| Flour |

600 |

7.0 |

1.05 |

(III) wall pressure system

Wall pressure system is the key link of bulk grain storage under lateral pressure, which is directly related to the safety of grain storage. In this design, the steel column is 6 meters wide, the column is of equal cross-section H-shaped steel, the column is made of high-strength H-shaped steel as the bearing wall beam, and the wall beam and the steel column are all connected by high-strength bolts (hinged).

A grain blocking plate is arranged on the inner side of the beam. The grain blocking plate is formed by cold pressing of galvanized sheet into a bearing plate. According to different grain bearing surfaces, the thickness is generally 0.7mm -1.2mm. This plate bending capacity is strong, not easy to deformation, vertical installation layout, no seams. The application effect is good after the pressure analysis of force calculation and the actual grain loading verification.

(IV) gable column compression system

In this design, the foundation ground anchor (as shown in the figure) and the foundation without ground anchor are set up 6 meters away from the wind-resistant column inside the warehouse.

(V) grain gate system

The design of the door using inside and outside two layers of doors, the outer door can be used 75-100 thick composite insulation sliding door, can also be used to seal the effect of better flat door. The inner floor door adopts multi-layer superimposed arc type heat preservation and grain blocking door. The height of each floor is 500mm, and the strength is guaranteed. Each floor door is closed layer by layer from bottom to top, locked with each other, and rises with the rise of grain surface. This design solves the problems of grain depression at the door and waste of grain loading space.

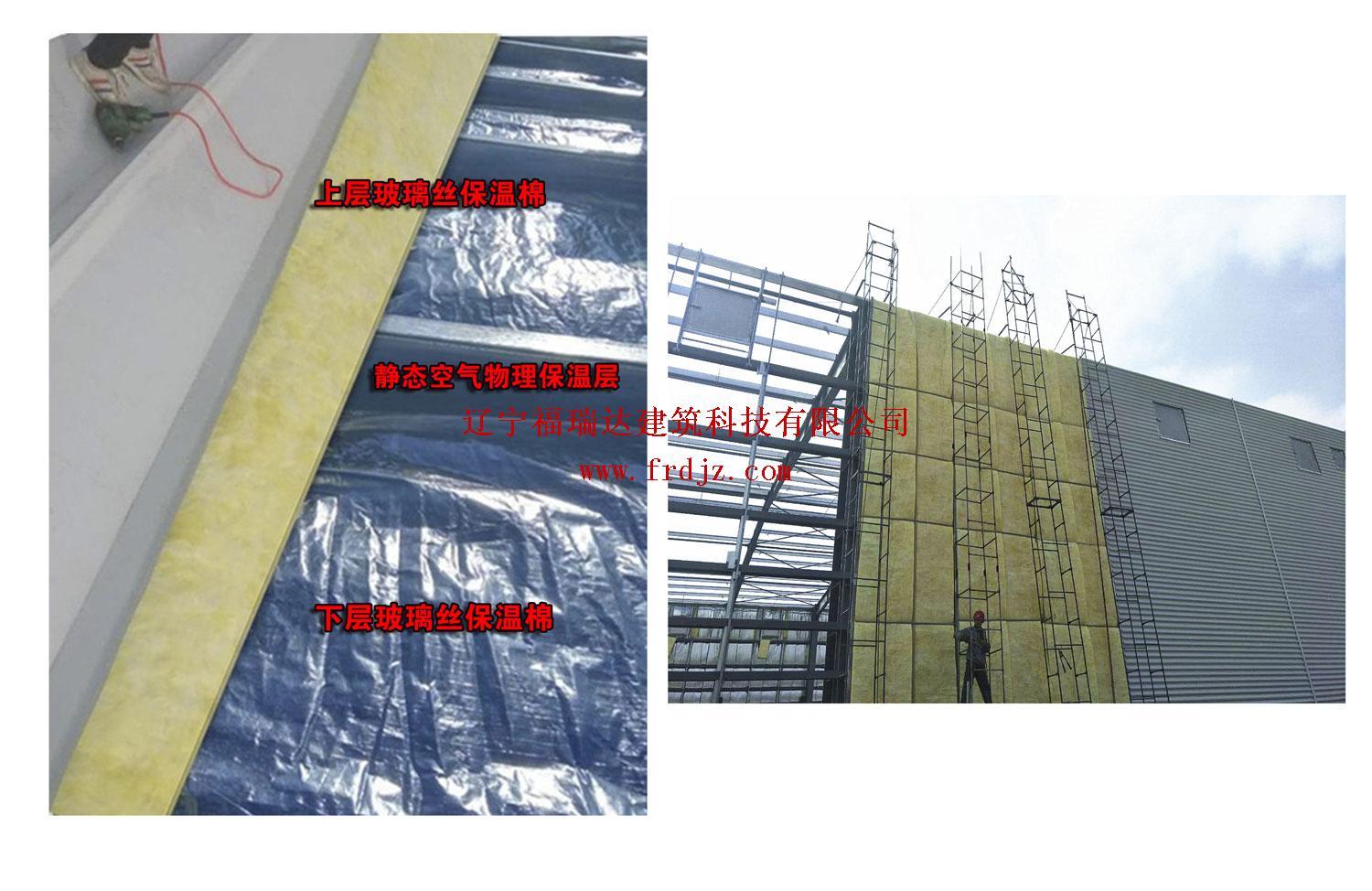

(VI) roof and wall insulation system

Wall insulation picture Roof insulation picture

Roof insulation with tin paper centrifugal glass wool, bulk density 18KG/cubic meter. A layer of 100mm thick glass wool is laid between the roof waterproof pressure-bearing top plate and the upper flange of the roof purlin, with the tin foil facing down; the lower glass wool is placed on the reverse hanging decorative board installed on the lower flange of the roof purlin, the tin foil is upward, and the glass wool is fixed with a pressing piece to prevent movement.

Wall insulation is made of centrifugal glass wool with tin paper, with a bulk density of 18kg/cubic meter. A layer of 100mm thick heat-resistant glass wool is formed between the wall bearing plate and the wall beam and between the wall beam and the outer waterproof color plate. The tin paper of heat-resistant glass wool faces the wall beam. The middle wall beam section of the two layers of glass wool is a static air physical insulation layer, which forms and achieves the heat preservation principle and effect of thermos.

(VII) wall and roof waterproofing system

The outer wall plate is made of color-coated plate with a thickness of 0.5 mm-0.6mm and a color of white or determined by the owner (it is better to use light colors such as white to reduce light absorption and heat accumulation). The plate type is FX780 type horizontal hanging plate or 1000 type vertical hanging plate, etc. The wall connection node adopts unique waterproof measures.

The roof of the traditional bulk grain depot adopts the traditional coiled material for waterproofing, and the wall adopts waterproof coating for waterproofing. However, these traditional waterproofing measures all have the phenomenon of internal seepage of water vapor after the aging of the waterproof material, and the grain is often lost due to flooding. Steel structure bulk grain depot. The wall is also the application of color steel plate, and the use of a unique node waterproof measures, there is no water infiltration and other phenomena, to prevent the loss of food due to flooding.

The bottom layer of the roof adopts the decorative bottom plate and is hung under the purlin.

The roof outer plate is made of color-coated plate with a thickness of 0.5 mm-0.6mm. The color recommend is white or determined by the owner (it is better to use light colors such as white to reduce light absorption and heat concentration). The plate type is 500. This plate type uses color steel plate with 360-degree gluing and double-lock sealing to make the roof, which has very good waterproofness, and the roof can move with thermal expansion and cold contraction. Compared with the roof of traditional bulk grain storage and similar grain storage, it can reach 100 to prevent leakage. The roof panel and purlin are connected by fastening brackets to reduce the exposed self-tapping nails and enhance the waterproof effect.

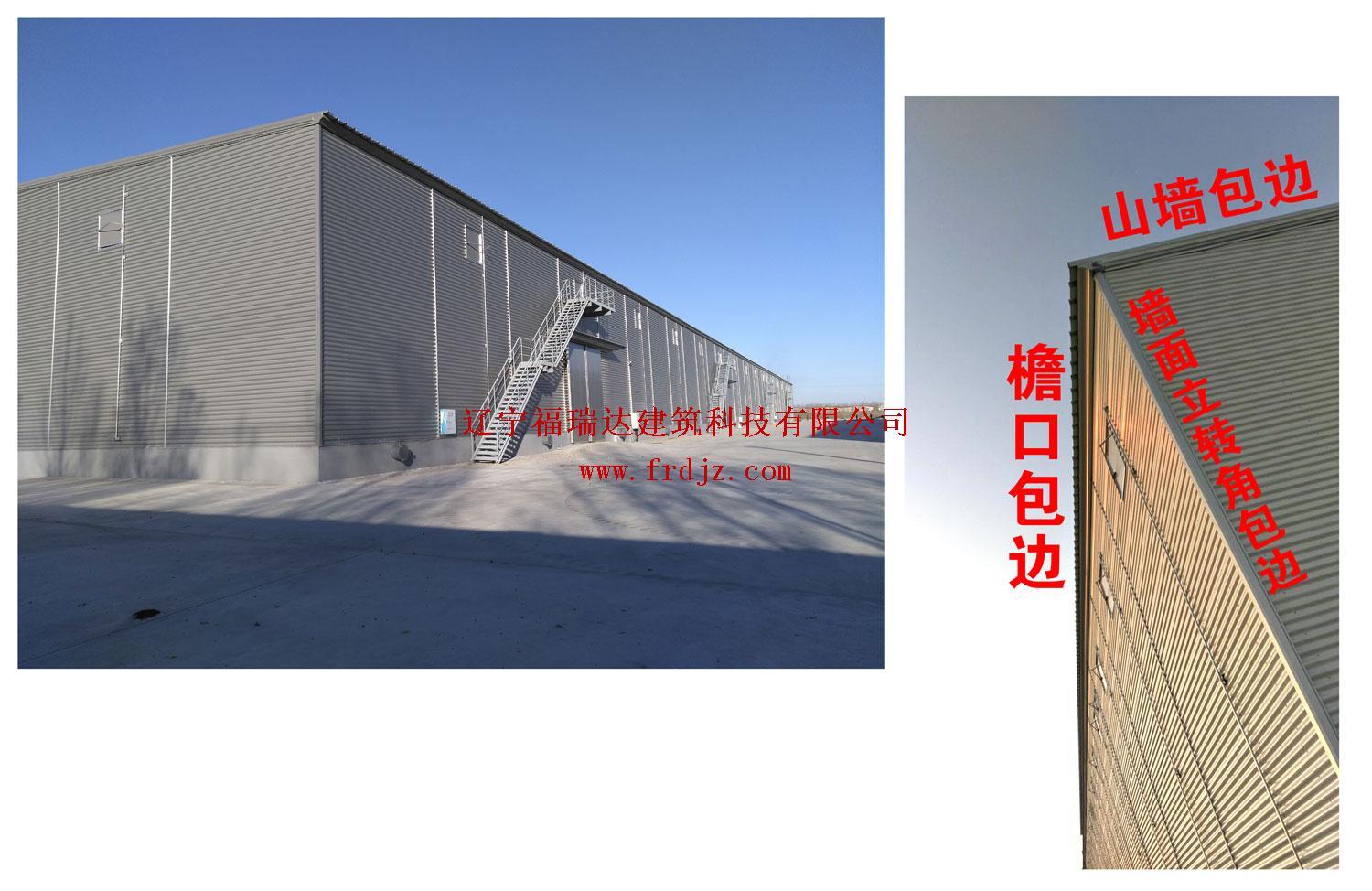

(VIII) hemming system

The design of the wall horizontal connection drainage pressure parts, ridge tiles, gable edge, eaves package, wall vertical corner edge for the company's patented products, using a special molding machine one-time molding, the length can reach any length, after installation is more standardized and more beautiful, waterproof effect is good.

(IX) grain surface air feeding system

In this design, 1200*1200 natural ventilation thermal insulation casement windows and 600*600 shaft wheel fan strong exhaust thermal insulation casement windows are set above each bay. Through lever transmission, personnel can open the casement on the ground. At 150mm from the ground, each bay is provided with a circular or square heat preservation ventilation hole with a diameter of 400-600mm, so that users can use a fan to blow air into its warehouse.

(X) ground system

The available steps are: compaction of plain soil, rolling of 250-thick rubble, leveling of fine sand (or 50-thick C15 fine stone concrete cushion), laying of underground waterproof grade plastic cloth or other waterproof materials as moisture-proof layer, glass fiber crack-proof net, 150-thick C25 concrete, calendering of the surface layer, and gluing of cutting joints.

(XI) Some engineering cases

1. Panjin Grain Depot Co., Ltd. 12#, 13#, 14# Rice Provincial Bulk Storage Warehouse

Due to the limited subsidy funds, the owner Panjin City Grain Depot can only complete the construction of 12# warehouse with the traditional construction mode according to the predetermined funds. Therefore, it applied for the construction of our patented steel structure grain bulk warehouse. After the application was approved in November 2015, it built 12#, 13# and 14# rice bulk storage warehouses with limited funds in January 2016, and successfully filled the stored rice to complete the reserve index. After the application, under the premise of all kinds of indicators are normal, the average temperature is 3 degrees lower than the original concrete warehouse in the hospital, and the good effect of storage energy saving is achieved.

2, Qiqihar Yinggang Hongtong Logistics Reserve.

The reserve is a 180000-ton corn reserve jointly established by Yingkou Port Authority and private enterprises. The bank was established in June 2015, broke ground in July 2015, and was completed and successfully used in October 2015.

3, Liaoning Zhongze Group Bayuquan new 100000 tons of reserves large warehouse logistics reserve.

Dacang Logistics Reserve is a subsidiary of Liaoning Zhongze Group, which is set up in Bayuquan and plans to build a new bulk grain reserve with 100000 tons of reserves in November 2015. The bulk grain warehouse of our patented products won the bid with absolute advantage in the bidding, and completed the warehouse construction in 45 days, and completed the task and delivered to use at the end of December.

4. Since 2009, we have completed steel structure grain bulk warehouses in Haicheng, Liaozhong, Jinzhou, Taian, Panjin, Xinmin, Qiqihar, Tangshan, Siping and other places.

Projects just completed this year:

(1) 50,000 Tons Corn Reserve Warehouse of Haicheng Tengda Feed Co., Ltd.

(2) Panjin Fengzeyuan Rice Industry Co., Ltd. 40,000 Tons Rice Low Temperature Storage

(3) Panjin Longmen Rice Industry Co., Ltd. 60,000 Tons Rice Low Temperature Storage

(4) Bulk grain railway station shed of Panjin Grain Co., Ltd.

(5) 1#, 2#, 3# rice storage bulk warehouse of Panjin Xinkai Grain Co., Ltd.

(6) Old Siping Grain Reserve Corn Bulk Reserve

(7) Rice bulk storage warehouse of Tangshan Cereals Rice Industry Co.

(XII) Patent Certificate

| Serial Number | Certificate No. |

Invention patent certificate |

Patent Number |

| 1 |

4283443 |

Steel structure grain depot and installation method |

ZL 2005 1 0067798.6 |

| Serial Number |

Certificate No. |

Utility Model Patent Certificate |

Patent Number |

| 1 |

4283443 |

Steel structure bulk grain depot |

201420748401.0 |

| 2 |

4429928 |

Steel structure grain depot arc-shaped retaining beam door |

201520089653.1 |

| 3 |

4450235 |

Steel structure grain depot vent |

201520089773.1 |

| 4 |

4450852 |

Pressure-bearing wall surface of steel-structure grain depot |

201520089634.9 |

| 5 |

4448361 |

Waterproof structure for grain depot |

201520089877.2 |

| 6 |

4450782 |

Steel structure grain depot cornice package |

201520089666.9 |

| 7 |

4468327 |

Steel structure grain depot gable edge |

201520089439.6 |

| 8 |

4495166 |

Steel structure rack for steel structure grain depot |

201520093139.5 |

| 9 |

4495844 |

Wall and roof insulation system |

201520093140.8 |

Liaoning FuRuida Construction Technology Co., Ltd.

Contact: Yang Litian

Tel: 0412-4945566

Mobile phone: 13464943646

Website: http:// www.frdjz.com

Address: Industrial Park, Tai'an County, Anshan City, Liaoning Province

More news

Fuqi (Anshan) Steel Structure Technology Co., Ltd. is another enterprise established by Liaoning Furuida Construction Technology Co., Ltd. in the high salary area of Anshan to achieve the three-year plan goal. We are recruiting the first batch of company members from the society and welcome people of insight to join our big family!

Application of Steel Structure Construction in Modern Architecture

Steel structure is a kind of building structure system with high strength, light weight and strong plasticity, which has a wide application prospect. This article will focus on the application of steel structure construction in modern architecture.

Steel structure construction industry scheme

As an advanced, energy-saving and environmental-friendly construction method, steel structure construction has been widely used in the field of modern architecture. This paper will discuss the importance of steel structure construction and industry program.

Steel structure construction matters needing attention

The construction of steel structure is a complex project, and many matters need to be paid attention to in the construction process to ensure the quality and safety of the project.

Common Problems and Solutions of Steel Structure Construction

Steel structure construction is widely used in the construction industry, but some problems often affect the progress and quality of the project during the construction process. This paper will analyze the common problems in the construction of steel structure and provide solutions.

Dynamic Interpretation of Steel Structure Construction Industry

As an important field of the construction industry, steel structure construction has shown new development trends and changes in recent years with economic development and technological progress. This article will interpret the latest developments in the steel structure construction industry.